Finishes + Services

In addition to our finishing options, we offer a wide range of value-added services from logistics coordination to polishing, warehousing, and direct shipping. We are here to make sure your project goes smoothly from start to finish.

Our Finishes

We offer the following plating finishes. Please reach out to our team with any questions you may have.

Blank

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Zinc Nickel Finishes

Zinc-Nickel: This alloy offers enhanced corrosion protection over conventional zinc plating. This finish is rapidly expanding in the automotive industry due to the superior corrosion protection afforded by this finish. We have this finish available in both acid and alkaline processes, in rack and barrel applications. We currently have 3 plating lines in production with an additional line in construction. Our processes provide the latest technologies of 12-16% Nickel alloy, thick film, trivalent passivates, and robust topcoat post-treatment options.

Zinc Finishes

Zinc: Zinc finish provides excellent ductility and adhesion. It is also ideally suited to combat corrosion of various metal substrates, some of which is due to its excellent chromate conversion coating receptivity. We offer both acid and alkaline zinc finishes on a total of 3 plating lines in both rack and barrel applications. Thick film, trivalent passivation, and robust topcoats are provided. Colored chromates and their respective sealants are available upon request.

Nickel and Nickel Chrome

Nickel and Nickel/Chrome finishes are ideal for the appliance, fastener, electrical, furniture, and automotive industries. Finish options include bright, satin, and duplex nickel. We also offer Copper/Nickel/Chrome for your zinc diecast substrates, and barrel tri-chrome for the fastener industry and small parts. We have 5 rack and barrel lines to support these finishes.

Electroless Nickel Finishes

Electroless Nickel can be applied to many different substrates including copper, steel, brass, and aluminum alloys. Due to the auto-catalytic nature of the process, E-Nickel finishes have far greater thickness uniformity over electrolytic finishes. We offer a mid-phosphorous finish in either rack or barrel process.

Silver Finishes

Combined with its excellent corrosion resistance and solderability, silver is the perfect finish for the electrical component industry and other niche markets. We have 2 silver plating lines that support both rack and barrel finishes.

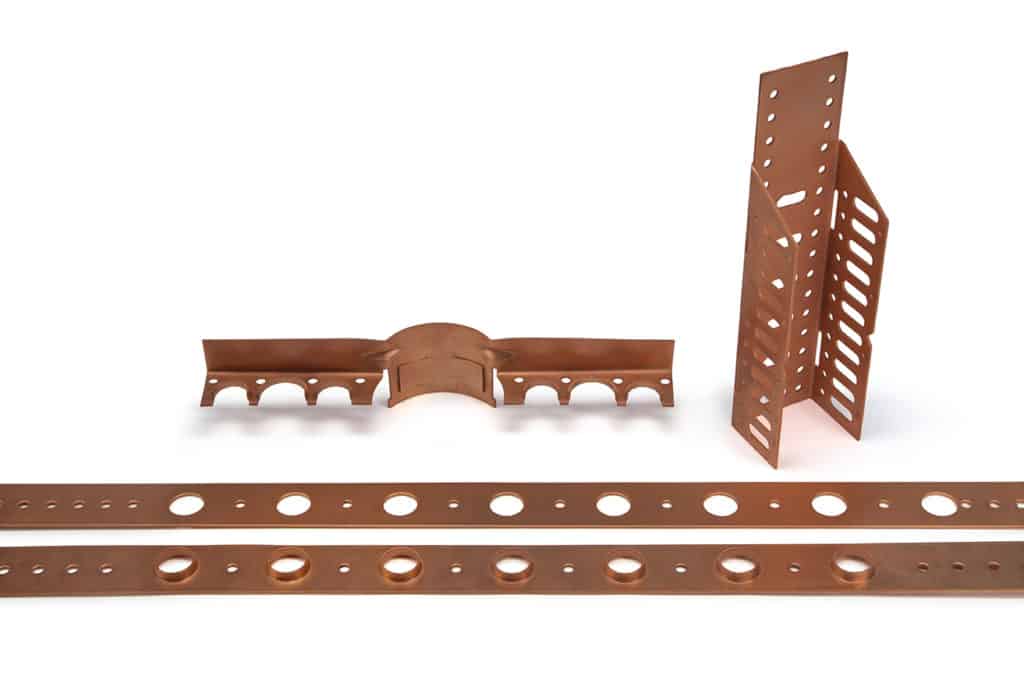

Copper Finishes

Copper finishes offer a variety of benefits due to their malleability, conductivity, corrosion resistance, and lubricity characteristics. We have 3 plating lines that provide Copper finishes over various substrates including steel and zinc die-cast.

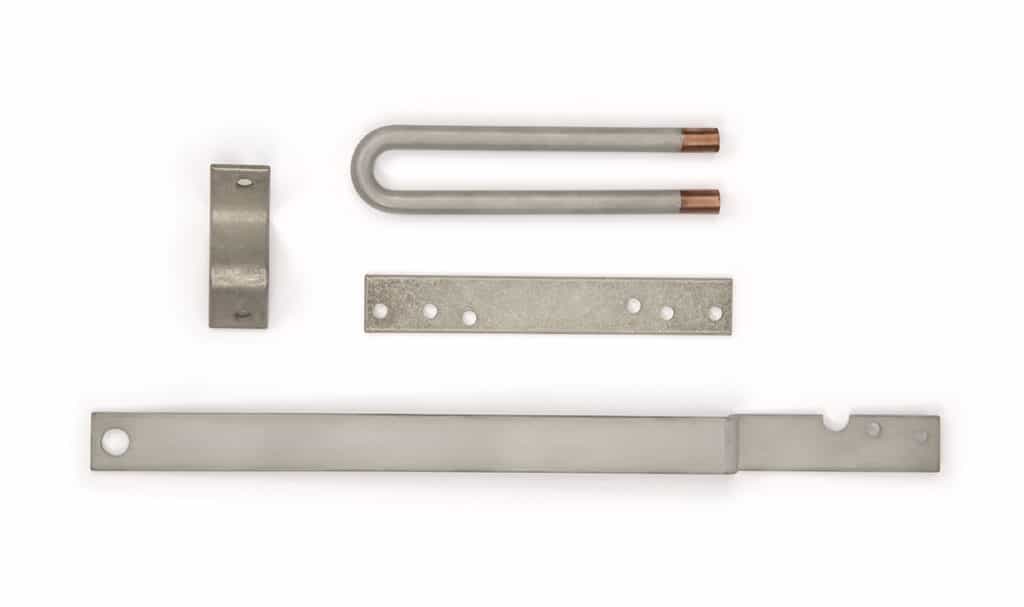

Tin Finishes

Tin finishes have the advantage when it comes to heat transfer and adhesion, good ductility, excellent lubricity, and resistance to wear, corrosion, and temperature. Tin plating is the solution to formicary corrosion in copper tubing for the HVAC industry. Tin is commonly used in the electrical component, refrigeration, and fastener industries. We offer both bright and dull Tin finishes on a total of 2 plating lines in both rack and barrel applications.

Additional Services

- Advanced Packaging

- Warehousing

- Direct Ship

- 3rd Party Logistical Coordination

- Assembly

Additional Finishing

- Hydrogen Embrittlement Relief

- Zinc Passivation

- Aluminum Passivation

- Aluminum Washing

- Vibratory Deburr

- Polishing/Buffing

Let’s Get Started

We’d love to help you with your next project. Give us a call at 432-623-0062, use the contact form on our contact page or start a quote request here.